Description

A specialist soundproofing material called Acoustic Mass Loaded Vinyl (MLV) is frequently used in a variety of applications to improve acoustics and lessen sound transmission. This is a summary of MLV:

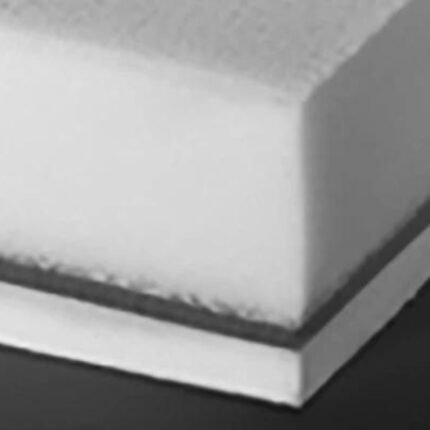

- Composition: To increase the mass of the vinyl, additional materials like calcium carbonate or barium sulfate are often added to high-density vinyl to create MLV. Being more massive helps to deflect sound waves, which makes it a good soundproofing material.

- Soundproofing Properties: MLV is renowned for its capacity to stop airborne sound waves from being transmitted, including noise from nearby loud neighbors, machinery, and traffic. It can be used to create a sound barrier that lessens sound transmission from outside sources or between rooms by installing it in walls, floors, ceilings, and other surfaces. MLV normally has STC ratings of between 20 to 34 or higher, depending on structure, density, and other variables. Better soundproofing performance is indicated by higher STC ratings; ratings over 50 are regarded as exceptional for effectively blocking the majority of airborne noise.

- Versatility and Flexibility: Acoustic MLV can adapt to a variety of uneven surfaces and shapes since it is versatile and easy to work with. It can be used to assist contain sound within a space or stop noise from entering by being laid behind walls, under floors, or wrapped around pipes and ducts.

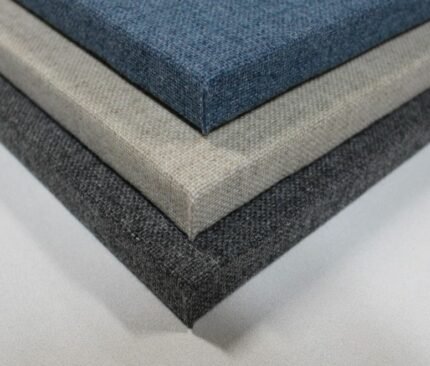

- Density and Thickness: MLV comes in a range of densities and thicknesses, with the thicker and denser varieties having better sound-blocking properties. The exact noise reduction needs of the application should guide the choice of MLV thickness and density.

- Installation: MLV is usually fastened directly to surfaces with mechanical fasteners, glue, or staples. To improve soundproofing, it can also be layered between layers of other building materials like plywood or drywall.

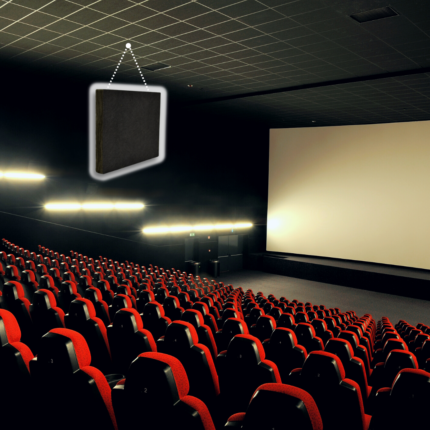

- Applications: Where noise control is crucial, acoustic MLV is frequently utilized in commercial, industrial, and residential environments. In order to produce quieter and more comfortable settings, it is frequently placed in home theaters, recording studios, offices, flats, hotels, and industrial facilities.

- Fire Resistance: In order to abide with safety and building requirements, many MLV products are offered with fire resistance. It’s critical to confirm the MLV product’s fire rating and make sure it satisfies the specifications for the planned use.

It is important to take into account various variables when choosing acoustic MLV for a project, including the needed amount of noise reduction, the installation method, compatibility with other construction materials, and budgetary restraints. Acoustic engineers and soundproofing specialists can provide advice to help guarantee that the selected MLV solution satisfies the project’s performance objectives and unique requirements.

| Weight and thickness | STC | Approximate decibel level it will be reduce |

|---|---|---|

| ½ Lb/sqft – 1/16″ thick | 20 | Normal Conversation |

| 1 Lb/sqft – 1/8″ | 26 | Loud Conversation |

| 2 Lbs/sqft – 1/4″ | 31 | Road noise |

Because mass-loaded vinyl is so dense, purchases larger than one unit require specific shipping arrangements. Densities of #0.5, 1, and 2 pounds per square foot are available in mass-loaded vinyl.

Please give us a call at (469) 452-4242 if you would like a personalized quote.

Please get in touch with us if you need more information or have any other questions.